The Single Strategy To Use For Digital Printing

Little Known Facts About Digital Printing.

Table of ContentsNot known Details About Digital Printing Digital Printing Fundamentals ExplainedNot known Facts About Digital Printing

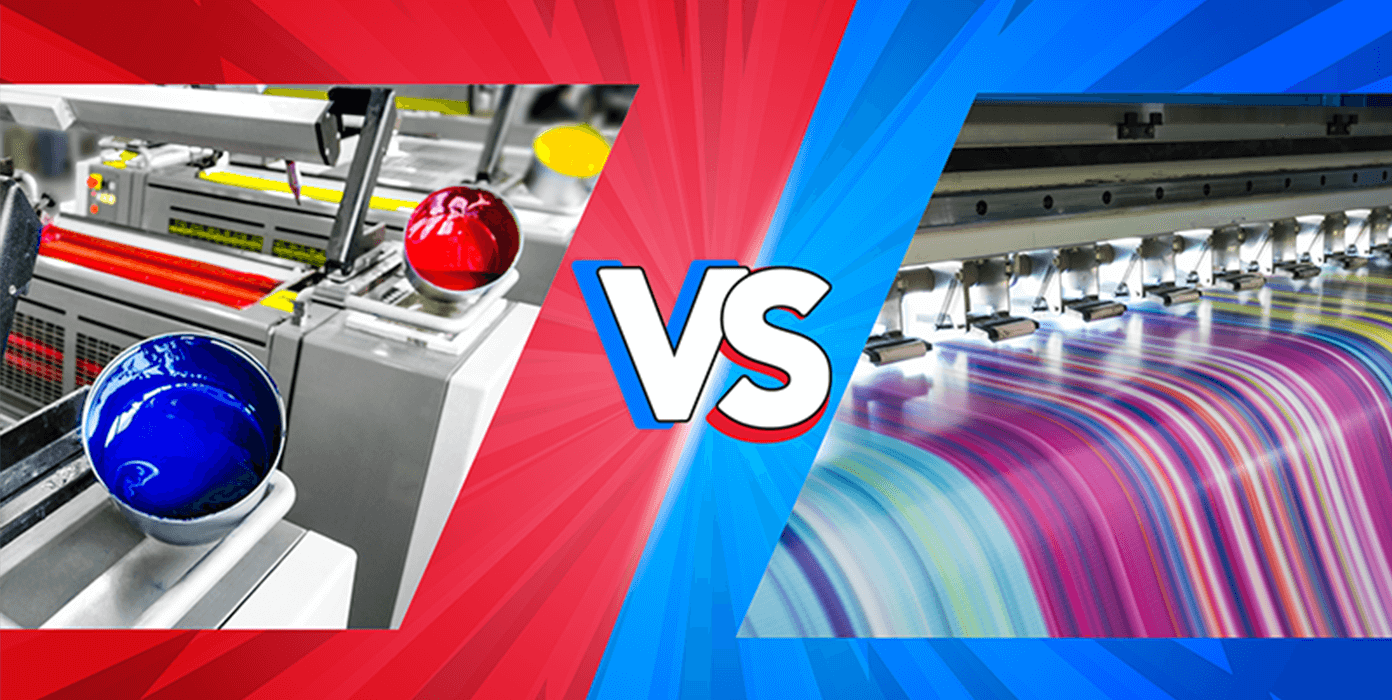

Traditional printing methods like Offset Printing have actually been the status quo for some time, and one of the greatest reasons is that at large quantities, it wins on cost. That's if you prepare to utilize a single design for all of your packaging - those days are over.Offset Printing calls for time and money to produce a Printing Plate, while Digital Printing enables you to simply submit an art documents( as numerous as you desire )to the Press. Today, most brand names underuse print personalization because they are simply unaware of the method's feasible advantages and that digital printing is the method to get there.

. With electronic printing, you have the power to create a make over for your display screen whenever you need a new production run. If you require a solitary layout for an entire project, after that maybe Litho is right for you. Yet remember, your up front spending plan and lead time will certainly need to be thought about. Required help making a decision Bennett is a premier packaging and retail display screens manufacturing company aiming to shield and promote our clients 'products with personalized corrugated remedies. We will certainly companion with you every action of the way. With our fully integrated design-to-delivery procedure, we can be the solitary distributor source. We are an award-winning producer of basically anything corrugate.

They vary in size and technology, but they allow you to post art documents straight to the press, instead of developing printing plates. Digital Printing is when you publish a digital-based picture onto some form of print media.

Litho Lamination( Offset Printing)is a typical printing method and was the most prominent option till recently. The advanced innovation electronic printing makes use of light solvents and much less harmful chemicals than even more typical printing approaches, such as offset and.

and copyright at Tetra Pak, share their experiences with electronic remedies and what their firms supply. Digital print enables food and beverage suppliers to run numerous plan variations in the very same print work, with almost no included expenditure or manufacturing time. This versioning capacity makes it possible to produce regionally certain product read this article packaging or carry out seasonal promos without big minimum orders. By offering full-color digital printing on our beverage containers, it will minimize design-to-print time and allow a variety of layouts in one order. Digital printing presents a whole lot of possibility for CPGs to react to some market needs that we're seeing today. Prior to, the food market for several years has been comprised primarily on the exact same product, same thinglike milk or juicehigh infiltration with exact same product. Health has comes to be a main point, brand-new networks with e-commerce, more affordable marketplaces with various other business and new start-ups. We started to see an extra granular market. This adds complexity to the sector; now you need to create more SKUs, or if a CPG concentrates on one product, they require to make certain they can attach with consumers at another level. It made use of to be CPGS would make a good item,

Some Known Details About Digital Printing

this process procedure much easier since go from a digital design straight to the printer, which can help aid lotWhole lot Likewise you can likewise adjustlike if you get a couple of days right into the packaging manufacturing or prior to the product packaging and you require to alter one word or something, it's a great deal simpler to make it happen.